RSS Flüssigboden

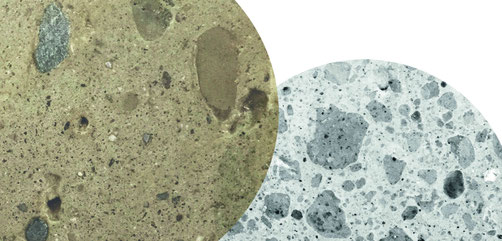

Source material

for the production of liquid soil is any type of excavated soil or other mineral substances. Liquid soil can be produced not only from any excavated soil, but also from selected recycling material without residual hydraulic components or components that change the moisture balance in an unplanned manner, and from other suitable bulk materials.

Additives

for liquid soil are specific plasticizers, accelerators, specific stabilizers, which can be described as soil-like, as they consist of materials that also occur naturally in the soil (eg clay minerals), as well as mixing water and, if necessary, special lime.Types and quantities of additives are unsuitable when they force the formation of macroscopic, rigid, cross-linked, solid foreign structures in the soil,and when they superimpose the properties of the source material and thus lead to rigid foreign bodies in the surrounding soil.

Stabilizer

An additive that further reduces the plasticity of the already placed liquid soil already reduced by an accelerator and thereby promotes re-solidification with the initial properties of the soil is referred to as a stabilizer. Cements and other hydraulic binding agents are not suitable as stabilizers as they lead to the formation of rigid foreign structures in the soil. An area backfilled with such a material behaves like a foreign body (eg under a road), which causes the known damage patterns of damaged roads. Only liquid soil as a soil-like backfilling material makes it possible to avoid such damage.

Plasticizer

The additive that allows the temporary flowability of a backfill material from soil etc. is called a plasticizer. The purpose of a plasticizer is to keep the mixing water in the soil matrix during the flowable state of the liquid soil (retention capacity).A plasticizer thus also enables the formation of a water film or sliding layers between the soil particles and thus the temporary flowability of the corresponding soil matrix.Plasticizers can be cellulose derivatives, bentonite suspensions, chemical superplasticizers, and special layer minerals. Their suitability must be examined and verified in each individual case.As plasticizers for liquid soil, specifically modified layer minerals have proven to be suitable.Even small quantities of these minerals can absorb rather large quantities of water in a soil and keep it stably and permanently under placement conditions.

Special lime

Special lime is used for conditioning extremely clayey or moist and non-free-flowing soils. Its special properties prevent uncontrolled post-hardening (pozzolanic reaction), as can be observed again and again in soils treated with conventional lime

Accelerator

At present, hydraulic accelerators are mostly used as accelerators. Hydraulic accelerators are cements with a suitable and specially required hydration process.They withdraw mixing water from the added plasticizer quickly and at a defined point in time.As a result, the sliding layers are degraded and frictional force is generated on the soil particles of the liquid soil matrix.Consequently, the previously flowable material becomes plastic. Afterwards, the remaining mixing water is permanently absorbed and bound by the "stabilizer", which is also added to the process.As a result of the plasticizing process, which can be controlled within specified time limits, the early load-bearing capacity of a liquid soil can be specifically adjusted and, if necessary, changed within certain limits.

Mixing water

The mixing water is the amount of water added to the liquid soil (depending on the required consistency) to make it temporarily flowable.